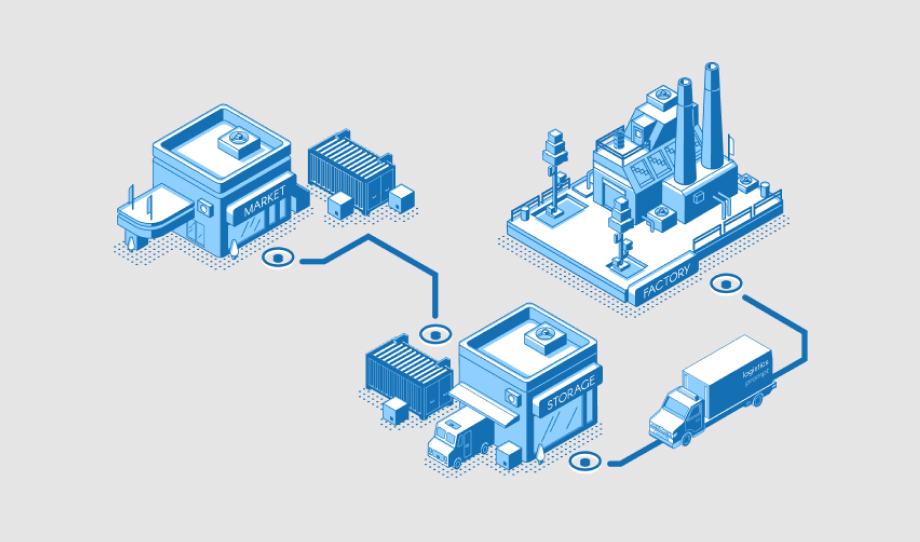

How Can Industrial Data Help Overcome All Business Challenges

Today, if we see the ongoing competition between industrial companies, we can easily underline the challenging…

How can Artificial Intelligence Boost the Manufacturing Industry?

Today, most of the Giant industries, around 83 percent, believe that AI delivers better outcomes; however,…

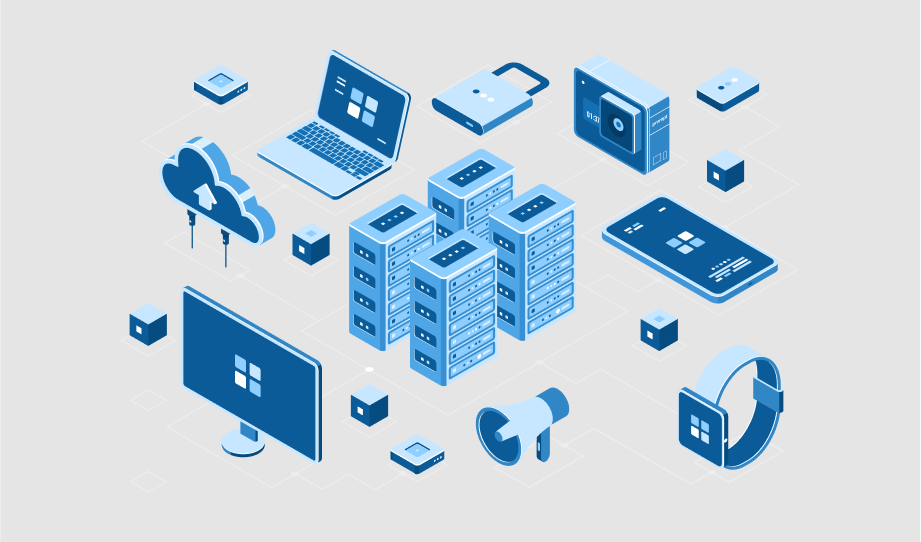

Which Solution is Best for Your Connected Device – Edge or Cloud Computing?

If you have adopted IoT and are developing an IoT-connected device, you may wish to do…

How To Build Smarter Apps Using Mobile Artificial Intelligence?

Mobile artificial intelligence is already revolutionizing the mobile app development game. In 2020, the mobile AI…

How is IoT Helping The Procurement Team in Improving Productivity?

Today, almost every device is connected; whether it is your smartwatch, air conditioner, or television, we…